Nope, Not Backstory.

I’m high and dry As of April 1.

Our trouble started all the way back last February, around the time we arrived in Lombok, Indonesia. We were in the midst of deciding which route to carry on with. We could have passed through by Bali and carried Westward across the Southern Indian Ocean back then, keeping our schedule on track and allowing us to round South Africa about now. But, Andrew really wanted to see Thailand. Andrew and Leslie were hemming and hawing about the additional year a trek Northward to Thailand would take while preparing me to stay over on my mooring ball while they make a trip home to pack up and sell their land-house. Andrew reaches down to pick up a floor board and access the bilge when I gasp.

“Oooh, hey, look! What’s that!?” I say, darting my eyes here and there, looking for something to distract Andrew.

“Just a minute, Sonri…” As he pulls up the floorboard and looks inside, his eagle eye goes directly to that problem I was hoping to hide. “Whoa.” His voice is grim, he reaches in and peels apart a keel bolt with his two fingers. The top of the bolt, 3/4 inches thick stainless steel, has all but parted from the rest of it’s body. It was hanging on only by the thinest of metal threads, waiting for Andrew to pluck it away. I groan as he holds it up to Leslie.

“What is that?” I ask, knowing exactly what it is but truly wishing not to know.

“It’s the keel bolt.”

I groan again. “How is this happening to me!”

Leslie takes the bolt between her fingers and sticks it closer to her eye. This is a grim finding indeed. Keel bolts hold my keel on. The “keel” is a big fin on the bottom of my hull made of 9,000 lbs of lead. It’s very important. It’s job is to counteract the sideways pressure of wind against my sails, allowing me to move forward at sea. Even more importantly, it keeps me upright. If the keel falls off, I will flip over and not flip back up. In that circumstance, I am very likely to sink, quickly, without much warning.

“It’s only broken a bit above the nut,” Andrew says, hopeful that maybe it doesn’t matter. “The part of the bolt above the nut isn’t even doing anything, right?”

“Yeah! Just the bit above the nut.” I say, longing to believe it’s not a big deal.

See? The nut is still there! It’s fine!

Leslie shakes her head. “If they are dissolving above the nut in fresh, open air, what are they doing below the nut encased in lead?” Andrew and I both deflate. We both know she is right. Stainless steel is strong, but remember my tutorial about crevice corrosion? Bolts at the lowest part of my bilge have undoubtedly been exposed to salt water and being encased in lead, they do not have good oxygen flow. They are very likely to be compromised.

“Yeah, but there are fifteen bolts!” Andrew says, again, hopeful that maybe it doesn’t mean what we all know it means.

“Yeah! Fifteen bolts…” I say, a little less certainty in my voice.

Leslie shakes her head again. “What makes you think the other bolts are much different?” To test this theory, Andrew grabs a hammer and begins smacking each of my other bolts. “This isn’t the first bolt to do this, either. Remember the one sketchy looking bolt we found when we bought her? This must be what happened I guess…”

SMACK! “Ouch!” The first bolt holds tight. “Yeah…” I say, glumly.

SMACK! I take a deep breath and steel myself for the third wack.

Andrew sighs. “Yeah, I know.”

“Well, I guess this answers our question regarding route.” Leslie says. Where we sat at the time, Thailand/Malaysia are the only reasonable options for making this kind of repair. We could sail South to Australia, but yard rates and labor rates there are sky high - even higher than the U.S. We could sail Westward to South Africa as quickly as possible, theoretically, but the Indian Ocean is known to be a more difficult area of the world for weather and currents. I should be at my strongest, just in case we face some bigger seas. The route up to Thailand and Malaysia is in protected water, mostly calm and flat, and the yards there are affordable, but with reasonable access to all the parts and pieces we will need.

I heave a big sigh. I know the right answer.

Leslie pats my and gives me a hug. “Oh, Sonrisa, it’s okay! We knew this could happen. We already researched it, remember? All we have to do is fix it and you’ll be good as new.”

“We are so close to the Indian Ocean.” It’s more of a groan than an actual statement.

“I know, it’s disappointing, but think of it this way. If we fix your keel bolts now, you’ll feel so much better. You’ll be good and strong for rounding Cape of Good Hope and South Africa.

Andrew begins shuffling through all sorts of research. Does anyone know how to do this here in Malaysia? Can we take the keel off and ship it to the US to be fixed? Can we buy a whole new keel in the US and have it shipped to us here in Malaysia? How much would something like that cost? He spends endless hours watching YouTube Videos or drinking beer with other sailors quizzing them on anything they might know about anything remotely related to keel bolts. They all know very little about keel bolts. Several ideas are proposed to simply drill an extra hole next to my problematic bolts and stick another bolt in there, but Andrew doesn’t like this. It seems like a bandaid measure that is not nearly as strong (or pretty!) as my current set up. He wants to rebuild me fresh as new, but how? Every night, he returns to me filled with more useless ideas bandied by Grog-Swallowed Sailors who have no idea what they are talking about.

“Get serious, will you?!” I demand. Leslie and I both hate this process of asking random people random questions and expecting to get any sort of valuable knowledge from it. But, this is Captain Andrew’s Way, and so we must be patient. He’s pretty good at sorting through what is right and what is the Grog talking.

Andrew sends an email to the Valiant Owner’s Group to noodle the question with all those who love my Sister Ships. A resounding response returns: “Ooooh, that sucks to be you. Call Fred.”

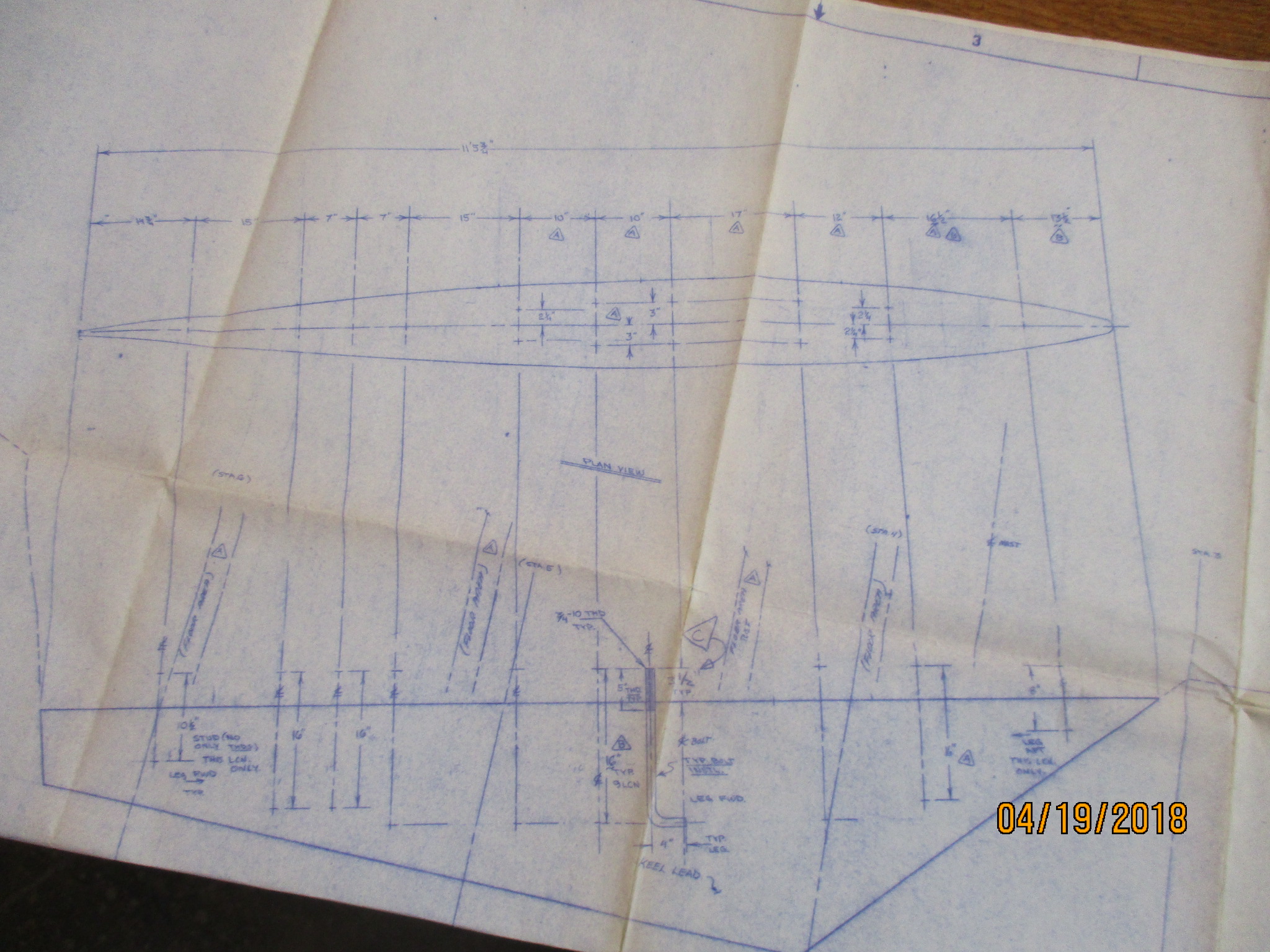

Fred is the well loved and well revered historian of all things Valiant. While we were first built in Bellingham, Washington (That’s where I was born), in 1983 or so, the Valiant manufacturer moved to Texas until 2011 when it ceased making new Valiants. Fred acted as Overseer of Texas Manufacturing, and to this day he is the Valiant Oracle and Keeper of Valiant Knowledge. Andrew calls Fred, who sends Andrew the blueprints for my hull with all the information about how my keel bolts are laid out, embedded in lead, and torqued.

Fred also delivers the unfortunate news that the mold from which my keel is made is broken and unusable, and therefore, unavailable to simply cast a new keel and mail it to us in Malaysia. There goes that idea.

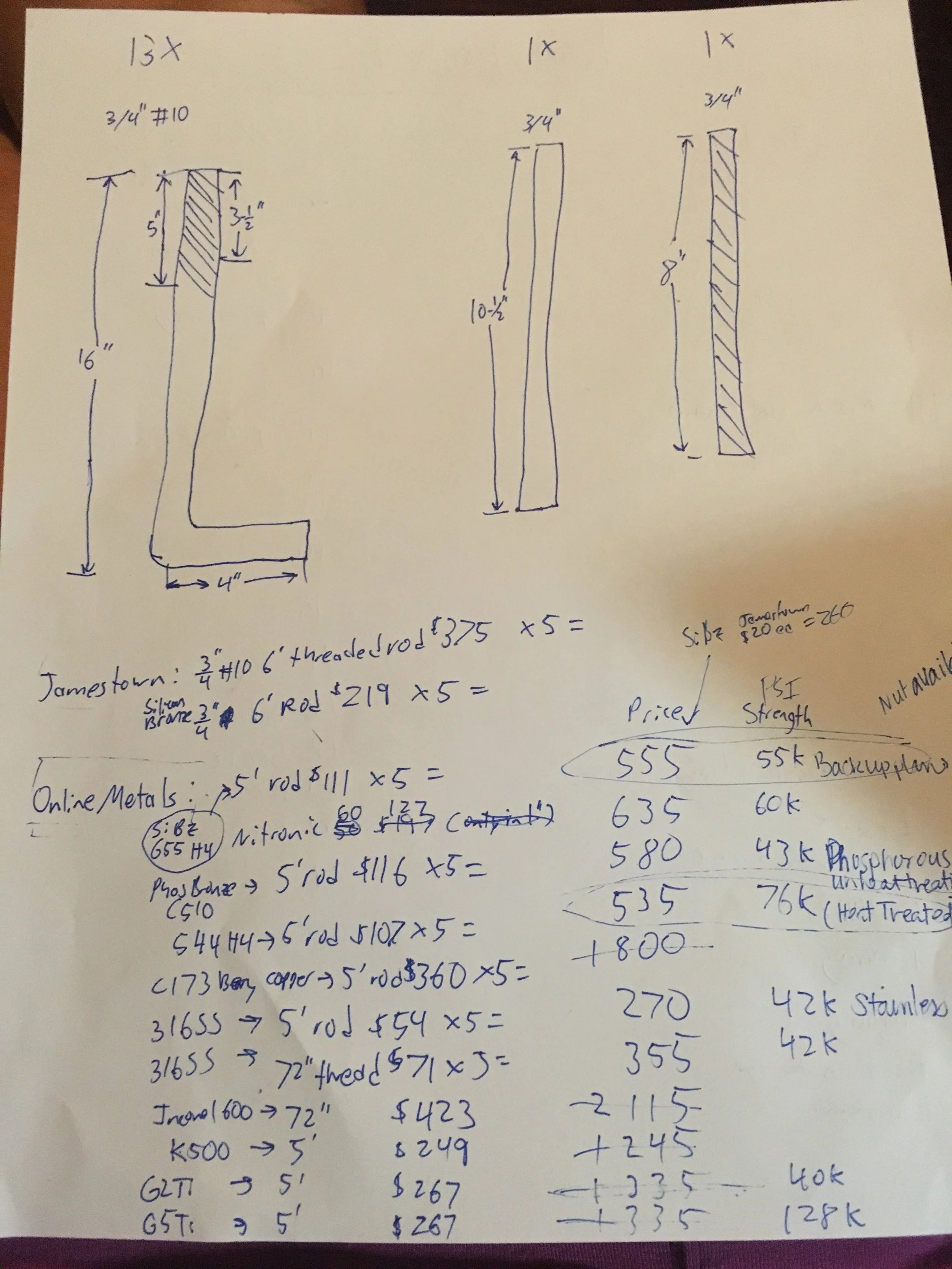

Andrew and Leslie study the blue prints, another round of metallurgy, and pricing for various options.

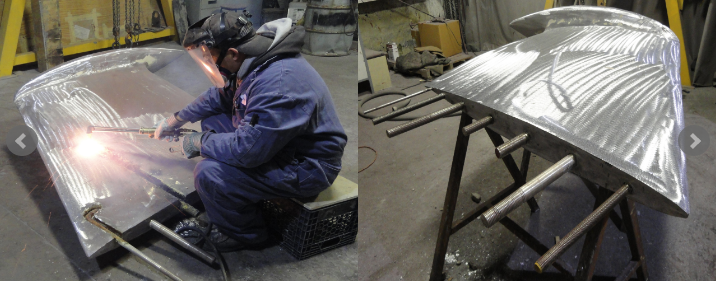

We consult with Mars Metals, an outfit in the US that handles keel repair. They break the news that shipping my keel back for repair will cost $14,000 one way, let alone the work and the shipment back to Malaysia. This is not ideal; not ideal at all. Andrew starts watching videos of the Mars keel people melting bolts out of giant lead keels; he imagines himself doing much the same:

After approximately a year’s worth of research and consideration, the answers to a few questions begin to formulate:

Who? My Captain Andrew, of course..

Where? At a yard in South East Asia, somewhere.

When? April 2019, after we enjoy the cruising season in Thailand.

How? With a giant oxy-acetylene torch.

And this is how we end up where we are today with me high and dry, in Langkawi, Malaysia.

Andrew in possession of a land-house and “Janis the Jalopy”

And, Leslie without her gallbladder.